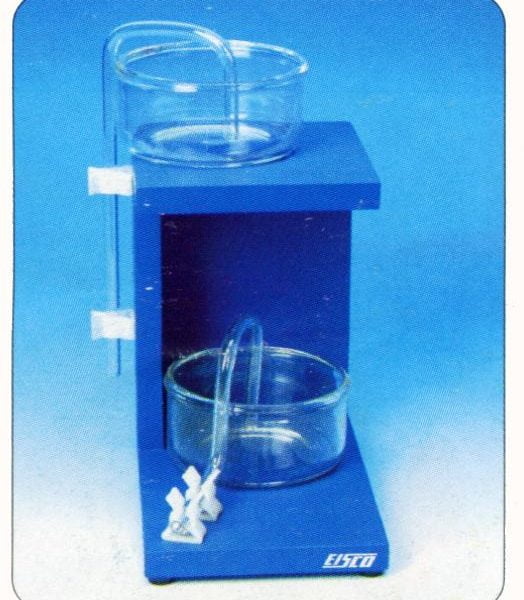

Electric Vacuum Pump

Electric Vacuum Pump. Very sturdy construction with great pumping capabilities for all high demand vacuum experiments.

Specifications:

Single Stage: RS-2

Pumping step (CFM) *: 2

Pumping rate: 4

Pressure: 10 – 30 Pa

Rotation speed (per minute): 1440 rpm

Air-Bleeding Speed: 2.5m3 / h

Power: 180Watt / 1 / 3Hp

Oil introduction: 220ml

Oil inlet valve diameter: Φ6

Dimensions: 319/125/243 mm

Weight: 11 kg

Power supply: 220V / 50Hz

The package includes the appropriate oil for the pump and hose.

* CFM: Volumetric flow of the valve. The volume of air that moves per minute.

It can be used for maintenance and repair of refrigerators, air conditioners, printers, car air conditioners, in medical instruments, in a chemical laboratory, in industries but also for photomechanical processes.

Labdisc

Labdisc Botzees

Botzees Edison

Edison Telepresence Robot

Telepresence Robot DOBOT

DOBOT Keyestudio

Keyestudio Fischertechnik

Fischertechnik